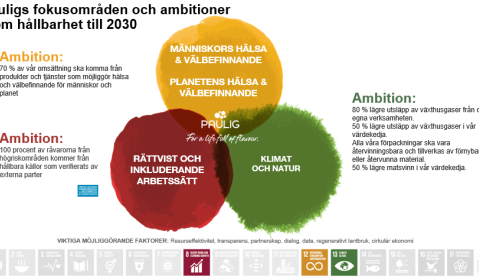

Our aim is to be a fair and inclusive partner and employer throughout our value chain. All our coffee is already 100% from verified sustainable sources and we aim to extend this work to cover also other raw materials. The goal is that all of our raw materials from high-risk areas come from sustainable sources verified by external parties by 2030. This will require more systematic due diligence process and a holistic way of working with our suppliers and other partners (e.g. civil societies) throughout our value chain. Furthermore, we commit to strive for transparency and living income in our key value chains.

We continue to develop our values-driven company culture to ensure that all our employee perceive Paulig as a fair and inclusive company. We want to excel in own personnel inclusion and have published our own Diversity, Inclusion and Equity policy to strengthen our commitment to a diverse, equitable, and inclusive workplace.

With almost 600 direct and 6,000 indirect suppliers and value chains stretching to nearly 80 countries, we have the opportunity to make a global impact. In addition to having a great opportunity for positive impact, we also have the responsibility to mitigate the risks – for example, when it comes to human rights, climate change or deforestation. As many of our impacts are in the upstream part of our value chain, it is vital that we ensure the mitigating activities and development programmes also take place there.

We cannot stress enough the importance of open dialogue and collaboration with our partners and suppliers and implementing our sustainability activities into our sourcing practices. During 2020, We have continued systematic mapping of our raw materials supply chain to increase our knowledge and the transparency.

We continuously develop our ways of working to further sustainable farming and responsible sourcing practices. 100% of our green coffee is sourced from externally verified sustainable sources, representing almost 80% of the total high-risk area share. The second biggest category for Paulig is spices & herbs.

During 2021, we created detailed, spice-specific roadmaps for our top 3 spices – black pepper, onion and Indian chilies – to start with. The goal for these top three spices is to have 100% of the sourced volumes from externally verified sustainable sources by the end of 2023. In 2021, 32% was already achieved.

The spices category will have an important role in achieving our ambition that all of our raw materials from high-risk areas come from sustainable sources verified by external parties by 2030.

Contributing to the wellbeing of future generations

As part of our ambition of being a fair and inclusive partner for all, we also want to demonstrate those attributes as a corporate citizen in the countries and communities where we operate and source from. Children and young people have always been at the heart of our initiatives, and we want to contribute to the wellbeing of future generations.

We support children and youth around the world by collaborating with for example the following organisations: Save the Children, International Coffee Partners, initiative for coffee&climate, Seeds for Progress, SOS Children’s Village Finland, Haiba Children’s Home (Estonia) and Mirada Jove Awards reward (Spain).